Gearbox Upgrade

Gearbox upgrade is one of the most common and direct performance upgrades for the gel blasters. It gives the gearbox an improved performance over their original expected performance and in many cases, increasing the gearbox efficiency so you can get more out of your blasters’ worth. Generally speaking upgrading a gearbox you are looking at a couple of things: Reliability, durability, FPS output and Rate of Fire. Importance of each aspect in that order. After all there is no point having a gel blaster that shoots extremely hard and fast but breaks down within minutes of usage.

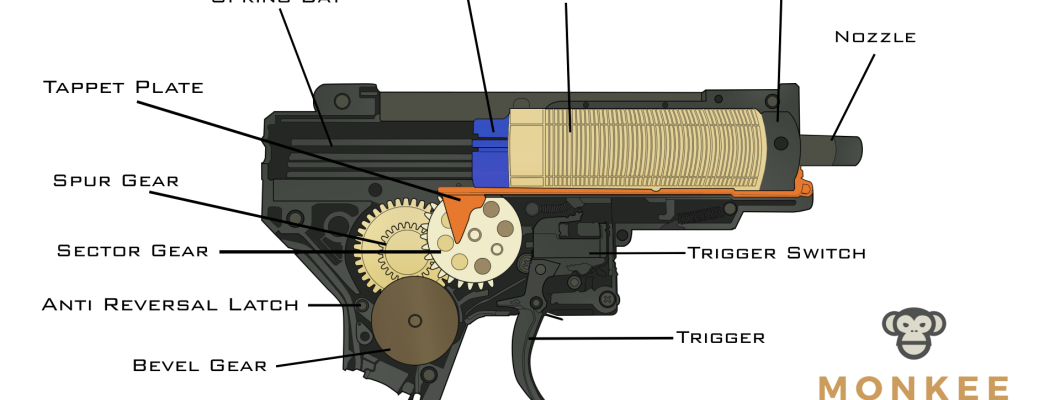

There are many parts of the gearbox to upgrade ranging from the gear set, piston rod, piston head, cylinder, cylinder head, nozzle head, and springs. If you’re stuck on where to start your gearbox upgrade, read on the topics below to have a more understanding of each part of the gearbox internals. Depending on which part you’ve changed, others parts may also need to be changed to make sure the parts are compatible/complement with each other.

For example, if you’ve changed the gears from nylon to metal, the piston needs to be changed with one that has a metal teeth rack because the stock piston is made to work with the stock gears and also because the harder material will chew off the softer material easily The piston head is an option change. Technically speaking, a stock piston head will work just as well as long as you make sure the seal is good and there is no vacuum effect issue.

For a stock V2 Jing Ji SLR gearbox, if you don’t want to change too much of the internals, you can change to High-Speed Nylon gears ( 18:1 ) and add a few shims to make sure that all the gears mesh together really well with minimal plays. This doesn’t affect the FPS performance of the gearbox, but if you want to have a much more responsive feeling on the trigger or a higher rate of fire you can instead put in 16:1 gears.

If you want to upgrade the SLR gearbox further you can opt to change the nylon gears into metal gears and a piston rod with metal teeth and don’t forget the piston head too, you will get an fps increase with the improved seal and your gearbox will be more durable. And because it's more durable your gearbox can handle a heavier spring which can give the FPS a nice boost.

Gears

The gear set found within the gearbox typically consists of 3 different gears.

Sector Gear - Pulls and release the piston rod

Spur Gear - Transfer the rotational energy from Bevel gear to the sector gear

Bevel Gear - Transfer the rotational energy from the motor’s pinion gear to the spur gear; a ratchet gear that interacts with the anti-reversal latch.

The standard stock gears inside the gearbox usually have a ratio of 18:1. There are many ratios for the gears from 18:1, 16:1, 13:1, and the difference is that they affect the rate of fire and trigger response. To explain how the rate of fire is affected when using lower ratio gears is because to make a full cycle of your gearbox the motor makes a full 18:1 rotations. A lower ratio gear will make the motor have to do fewer turns to complete a cycle through. However the motor will use more power per turn to do the same amount of work as the 18:1 gear, so it is more beneficial to have a higher torque motor when using lower ratio gears.

Anti-reversal latch is a part of the gear system that latches on the ratchet teeth on the bevel gears to prevent the gear set from reversing when the motor is off that can cause damage to the motor, battery and also the tappet plate.

Piston rod and head

The piston is the main component responsible for compressing and creating the air pressure to propel the water gels. There are many designs for the headpiece of the piston each contributing to how they affect the airflow inside the cylinder. Another important factor is that if you have metal gears it is mandatory to change the piston rod with metal teeth so that the nylon material won’t be chipped and prematurely worn out by the metal gears, especially the sector gear which interacts and moves the piston back and compresses the spring.

Ported cylinder and cylinder head

The cylinder helps to seal the air inside and direct the air towards your t-hop. What is happening is that the air inside the cylinder is compressed and forced out by the piston head, propelling the gel. The cylinder also dictates the air volume capacity and is an important factor to consider when you build a gel blaster. Excessive air volume on a short inner barrel length setup can cause low FPS because there simply is not enough back pressure generated enough to shoot out the gel at full potential before the gel leaves the inner barrel. This is what is usually referred to as the air cylinder to inner barrel air ratio.

For example, if you have a 100% non-ported cylinder matched with a 13cm inner barrel, the FPS will suffer and you will hear a loud pop when the piston head hits the cylinder head. On the other hand, if you have a 40cm inner barrel with a 50% ported cylinder, the FPS will also suffer because there is not enough air volume to fill up the inner barrel to propel the gel out properly. Ported cylinders in different air volumes are available to match the length of the inner barrel.

An important note is that the stock blaster cylinder head typically only has 1 O-ring sealing which is sufficient usually, however, some metal cylinder heads have more than 1 O-ring which will ensure the best air seal possible. There are also different types of cylinder heads, some will make your gearbox work more quietly and some will have a better air seal and won’t make much of a difference for sound. Compatibility is also important for what type/model of blaster you are using, while most gearboxes function essentially the same, some needed a slightly longer cylinder head, and some made for that specific model. So read the description of the product for its compatibility.

Nozzle head

The piece that directs air produced into your T-hop. Technically speaking, the Nozzle head has 2 jobs, first, it works along with the tappet plate to allow the gel to be chambered into the T-piece, second is to provide a good seal and directing air to propel the gel from the piston/cylinder. The stock nylon nozzle head usually doesn’t come with an inner O-ring that will cause a bit of an air leak. If you want to squeeze as much performance as possible you can change it into a nozzle head with inner O-ring. For compatibility it won’t be much of an issue due to most of the cylinder heads coming as a set with its proprietary and respective nozzle head. if it doesn’t you can use the nozzle head designed to fit your blaster model.

Spring

The spring affects the gearbox FPS output directly. There are many different spring loads for the spring ranging from M80 to M125 and more. The heavier the springs the faster and harder the piston inside pushes the air out. It’s best to use metal gears when the weight of the spring is M80 or more because the stock nylon gears will certainly be damaged from the tension of compressing the spring.

Nylon Tappet Plate

The tappet plate is an often forgotten but important piece of a component within the gearbox. Without it your gearbox would not fire a single gel pellet out. It is the component that connects the nozzle and the sector gear together via a fin of the tappet plate and a nub on the sector gear. This mechanism allows the gear system to cycle the nozzle back and forth to feed the gel from the magazine into the T-hop. Under normal circumstances the tappet plate is not a component that breaks easily and will usually last a long time. If you find your gearbox has a tappet plate breakage issue frequently you might want to look at the other parts compatibility that may have forced the tappet plate in a way it is not intended to. The most common way a tappet plate can be broken is a failed anti-reversal latch.

Non performance changes:

Trigger

The trigger doesn’t affect the performance of the gearbox directly, however for the user it can differ based on the personal preference and ergonomics operating the blaster itself.

Heat resistance wired

Replacing the stock wiring with a heat resistance wire ensures that the wire of the circuit won’t be damaged from the heat of the motor when firing. The wires are also much more durable than the stock wires in most V2 gearboxes.

MOSFET

A MOSFET ( Metal Oxide Semiconductor Field Effect Transistor ) is an electronic device that is used on many electronic devices for switches. What the MOSFET does is regulate the electrical current in the circuit. The MOSFET also has many other features that make direct changes on how the gearbox will behave and perform. For example the MOSFET will enable stable semi-auto firing, programmable burst firing mode, active motor braking and battery over discharge protection etc.

Metal Gearbox shell

A metal gearbox shell upgrade would be very beneficial because it is inherently more durable and will last longer. Unlike the nylon or polycarbonate gearbox shell that can flex during operation, the metal gearbox will remain solid to ensure the stability of the gears and components within.

Be very careful choosing the metal gearbox shell, as some may not have the same construction as the original gearbox shell. An example is the SJ Metal gearbox shell. It does not have the section on the gearbox shell to place the mag priming switch. Some gearbox shells may not fit certain receivers without modification.

Leave a Comment